This equipment is used to complete the washing work of plastic medical waste bins such as surface cleaning to remove dust and bloodstains, and to remove water from the washed plastic bins.

Water consumption: about 2-3T / 8 hours per shift

Electricity consumption: about 25 degrees/hour Steam heating

Steam consumption: about 120Kg/hour

Number of operators: 2 people 1 person is responsible for the upper box and 2 people are responsible for unloading the box

Equipment material: national standard 304 stainless steel

Equipment flow

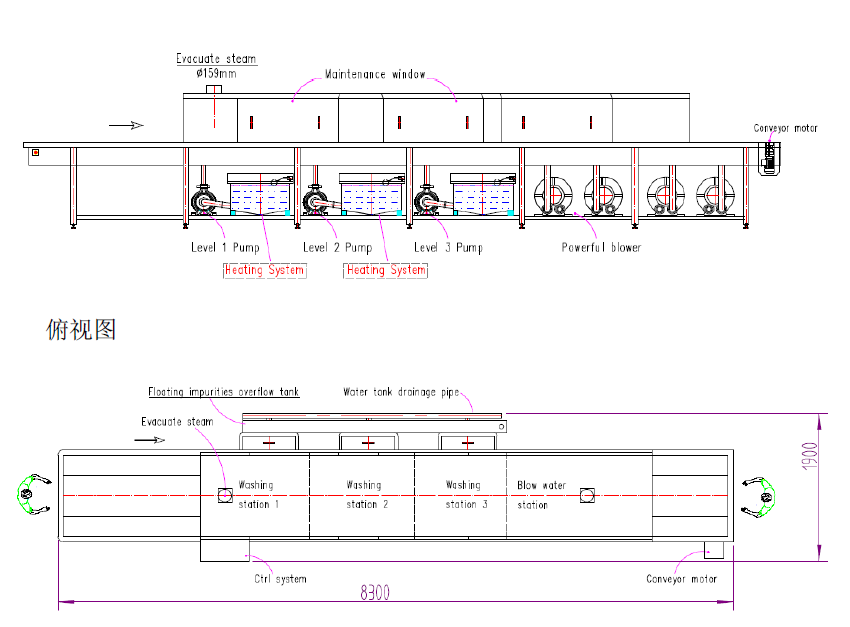

Manually placed into the empty box → pre-cleaning decontamination (solvent cleaning) → high-pressure cleaning (high-temperature sterilization) → disinfection (drug disinfection) → in addition to water → output → Manually take the box

The crate to be cleaned upside down / side, placed in the entrance of the cleaning machine, driven by the motor into the cleaning and disinfection tunnel, the drive chain on the pillar chain to drive the material to complete the cleaning and disinfection, and other aspects: the first is the first level of cleaning, dilution cleaning box, cover attached to the dirt; the second link is the main cleaning process, with high temperature and high-pressure spray water on the box for high-temperature disinfection rinse; the third link is disinfection water cleaning, adding disinfection solution to the tank for box disinfection; in the up and down full coverage of the cleaning tunnel, the box for a full flush; cleaning and disinfection after the end of high-pressure water removal finally driven by the drive chain box out of the work area, personnel will take out the yard.

Technical Requirements

| 1 | Applicable container type | 100L medical waste transfer box |

| 2 | Equipment capacity | Max 500 pieces/hour |

| 3 | Loading and unloading method | Manual |

| 4 | Processing method | Hot water washing + room temperature water washing |

| 5 | Heating method | Steam heating |

| 5 | Power supply | 380V 50Hz |

| 6 | Equipment power | Approx. 27 Kw |

| 7 | Inlet and outlet | Automatic water inlet, unified drainage |

| 8 | Water level protection | Each water tank is equipped with water shortage protection |

| 9 | Emergency stop device | 3 places, located in the distribution box, import and export each 1 |

| 10 | Control voltage | 24V |

All the plates used in the whole machine are 304 stainless steel, the thickness of the main body is 2mm, the thickness of the water tank is 2mm, and the thickness of the cover is 1.2mm.

1、Equipment size: about 830020001800 mm.

2、Corrosion-resistant stainless steel pump: pre-wash pump 4Kw, main wash 7.5Kw, disinfection pump 4Kw, overflow parts (pump head) 304 material.

3, conveying speed: 2-10 m variable frequency setting, can meet the cleaning task of 500 pieces per hour, the use of hypoid drive motor, oblique gear transmission high efficiency of transmission, not easy to break; solid drive shaft, stainless steel chain.

4、Transmission mode: continuous through the double chain type pillar chain conveying, to be cleaned by the chain and bracket to hold up, to avoid the box and shelf friction and affect the service life.

5, cleaning mode: from the upper and lower left and right to the material cleaning treatment, the ratio of the nozzle and the pump head and flow match, otherwise, it will cause the pump current is too large, the temperature is long high, and damage the pump; the bottom of the main channel of the low end to do quick-release structure, personnel can regularly clean the spray pipe dirt off.

6, heating method: steam heating, angle seat valve configuration with ESG angle seat valve, the benefit is that the valve has the function of waterproof water hammer, control steam solenoid valve is Adecco (Taiwan brand Ningbo factory), the installation of the valve body using SMS live connection.

7, filtration method: pumping skip stainless steel filter, in addition to the filter above the water tank, the inlet end of the pump also has a filtering device to prevent debris from entering the pump.

8, into the drainage way: tank unified automatic water, the tank is installed on the automatic water control device, to reach the highest level design to stop the water, below the low end of the liquid level cut off the pump power to protect the pump; drainage unified drainage, unified drainage as long as a hose connected to a place can be

9、Operating mode: centralized power supply for button control, unified operation box control, internal parts are Chint electrical appliances and Weichuang inverter, equipped with phase sequence relay, the operation button part is controlled with 24V safety voltage. Inlet and outlet end plus emergency stop, with problems at any time stop.

10, the water tank 2mm thickness, inside and outside fill wire welding, this is very critical, steam through the tank will produce shock, the general welding will cause the tank open welding. Water tank internal steam piping using a double layer, with a certain sound-deadening effect.

11, nozzle using stainless steel nozzle, the steam heating temperature is high, the plastic nozzle will fall off when working.

12, the inlet and outlet end of the equipment made of rounded corners (non-right angle), will not touch the operator.

13, in the need to pay attention to the place labeled with eye-catching stickers.

14, the equipment above the steam vent is reserved, otherwise, the workroom will be foggy when working.