KANZDA’s Crate washer is made of food-grade 304 stainless steel plates and profiles, and the conveyor system is made of unique thickened chains. The washing channel is customized according to the size of the crate, which is perfectly compatible with the size provided by the customer. Most crate washer is operated by two people but also by one person.

KANZDA is a professional manufacturer of revolving basket cleaning machines. The company adheres to the principle of satisfying users’ needs with quality. We do not make shoddy products. Each product is like our own children. We must first satisfy ourselves before leaving the factory.

With the development of society, an egg tray cleaning machine is available. The pace of life is accelerating, and more and more industries have developed to higher efficiency, such as some using turnover baskets, food factories, bakeries, pig slaughter, Poultry, duck and rabbit slaughtering and processing industries and supermarkets, clean vegetable processing, etc. have gradually developed from manual cleaning baskets to turnover basket cleaning machines. Now the workers are paid high, the cleaning is not clean, and the weather is unwilling to do it. The washing machine has a good cleaning effect. The current revolving basket washing machine is clean and fast. The Ningxia egg tray washing machine can also play a role in sterilization. The basket washing machine has a wide range of applications. It is used in the turnover basket cleaning machine in the turnover industry; the food box cleaning machine in the food industry; it can also be used to wash very dirty chocolate trays. The hardware industry can be used to clean processed parts because cleaning the baskets requires a lot of labor, and the degree of cleanliness also has certain limitations. To consider the purpose of customers, Zhucheng KANZDA Machinery Co., Ltd. absorbs the advantages of advanced equipment at home and abroad and tailor-made feasible equipment for you.

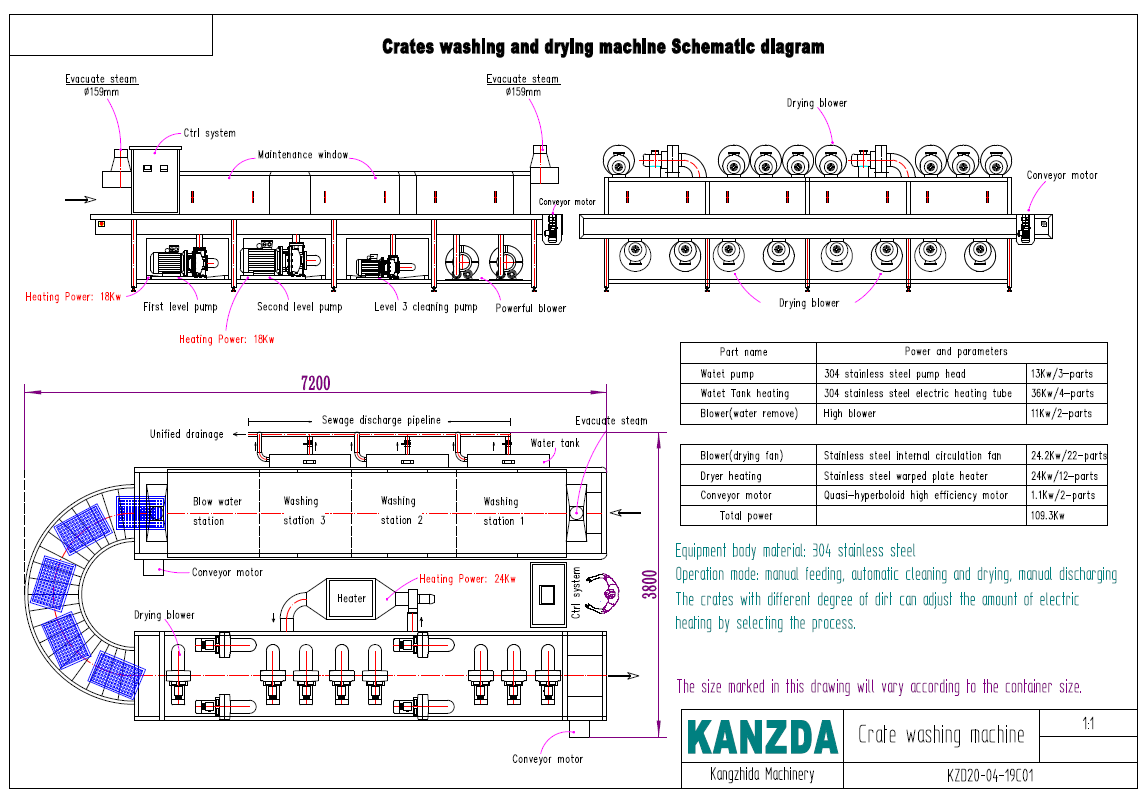

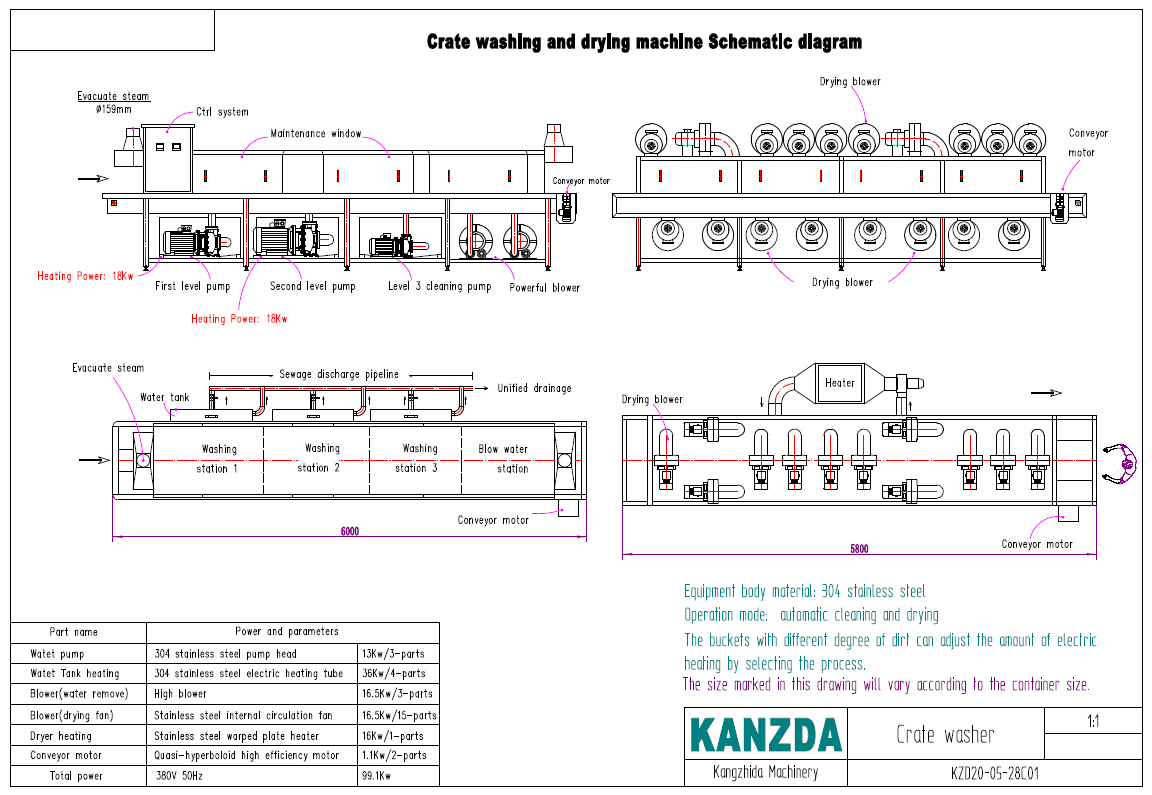

This is a large crate washer because the length of the machine with a drying function will reach 11.6 meters, and it needs to be transported in a 40 cabinet.

The washer can be made into an inline or “U” shaped design, which is essential for the customer’s cleaning room, and we will design according to the customer’s site conditions.

This machine is designed as a crate washer cleaning machine operated by 1-2 people, and the operator of this machine is responsible for the in and out operation of the crate.

The operator will put the crates into the feeding part of the washing machine. The crates will automatically enter the washing channel to complete the washing, water removal, and drying processes. When finished, the conveyor belt will output them to the unloading end, and the operator will put them into the centralized storage point of the crates.

1. Process requirements:

1-1. Workpiece size: plastic crates, 600x400x220mm, or other sizes.

1-2. Workpiece material: Plastic

1-3. Theoretical design output: 150-300 pieces/hour

1-4. Loading and unloading methods: manual loading, collecting, and collecting

1-5. Treatment effect: clean up oil stains and metal dust

(Stubborn stains, plastic damage, and aging are not required) dryness is about 99%

If you have more requests or other forms of machines, please leave us a message, and we will contact you as soon as possible.