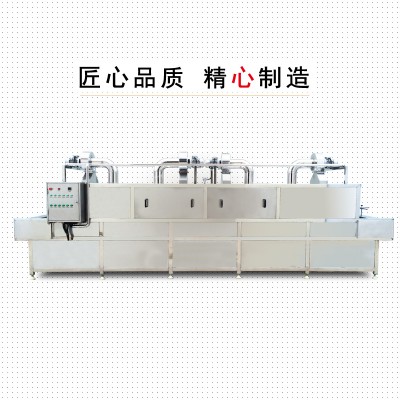

Chocolate mold cleaning machine: The main cleaning requirements for the mold surface are to wash off a layer of oil, wash the residual chocolate in the chocolate mold groove, disinfect, and sterilize.

Most of the chocolate molds are made of PE material, so it is not easy to use the solution with too high a temperature to process in the process of operation, the water temperature needs to be controlled within 60 degrees Celsius, and the height of the regular molds is below 4cm when running in the automatic mold cleaning machine, there needs to be a resistance to make it go smoothly if you need to add brushes, please pay attention to the brush to the mold gap as much as possible can be adjusted to meet the different types of molds can be processed with the same equipment. The same equipment can be used to process various kinds of molds.

In the cleaning process, add a degreasing agent, to avoid producing a large number of foam, as far as possible with food-grade lye as an auxiliary detergent, and will not produce harmful substances in the use of molds sticking to the surface, it is recommended to carry out a multi-cylinder cleaning, the middle of the main cleaning with a pressure of 5Kg head of stainless steel pumps, rinsing can be used with a small flow rate of water pumps, decontamination of the cleaning section of the stainless steel pumps with a large flow rate of circulation.

Safety performance should be done without safety hazards, emergency stop buttons in and out of the mold end are equipped;